Semi-Dry Cast Stone

Our product range

Why choose semi-dry cast stone?

When short lead-in times and cost efficiency are paramount, our semi-dry manufacturing is the answer. Production standards and materials are still of the highest order, but the processes are tailor-made to reduce costs and save time.

A key advantage of semi-dry cast stone is that multiple casts can be taken from each mould at a quicker rate, due to the lower water content. The mould can often be removed from the finished piece almost straight away. This technique requires no secondary finishing or treatment and can be supplied to you in most colours to closely match existing stonework.

Bespoke design and product features

Semi-dry stone boasts fast, cost effective manufacturing process and shorter drying times that allow moulds to be quickly reused meaning this stone suits tight budgets and timescales.

Semi-dry stone offers versatile colour matching with existing or proposed adjacent surfaces and features making it an ideal technique for regular standard architectural features such as copings, cills, heads and string courses.

We’ve designed our semi-dry casting process to meet tight budgets and deadlines, but craftsmanship and care are still applied in every way. All aggregates and materials are UK-sourced and you will always benefit from our meticulous service and professional support that add value throughout each project.

For more information, or to arrange samples, contact our team who will be happy to help.

Semi-Dry Stone / Design gallery

1 / 10

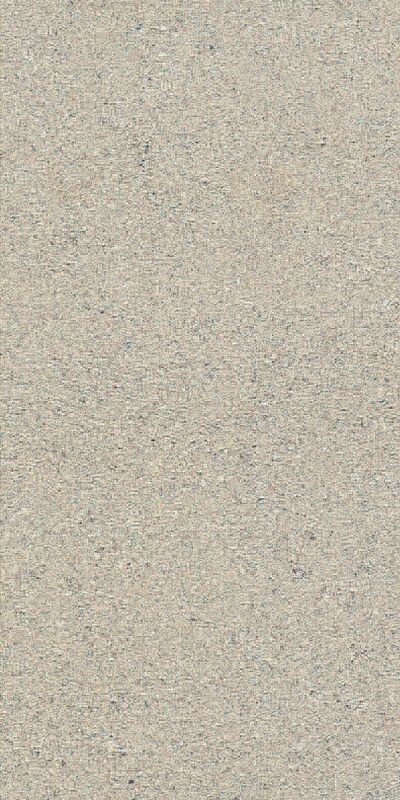

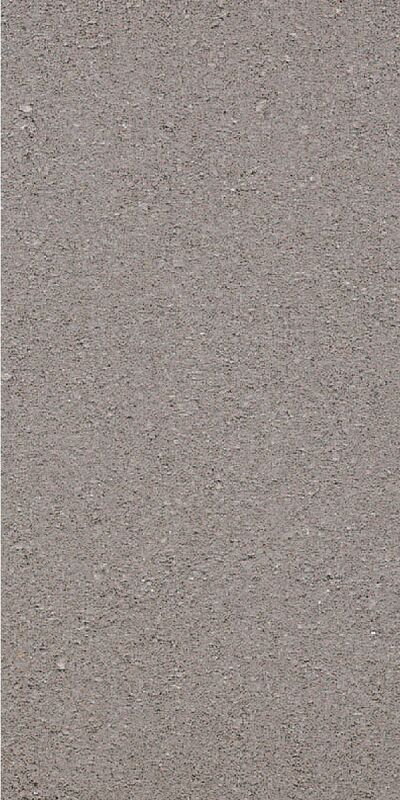

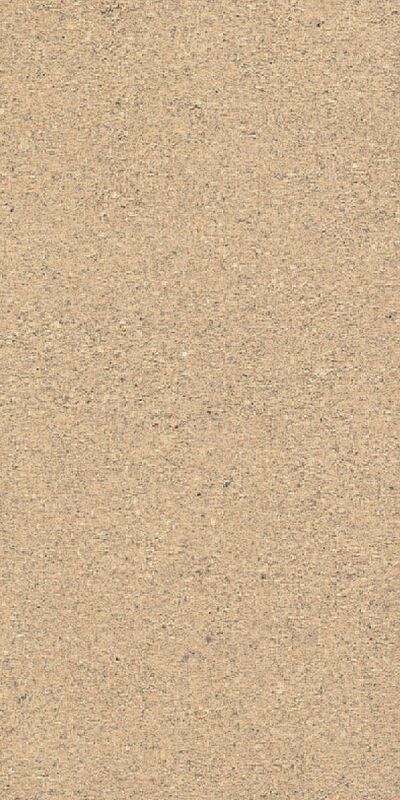

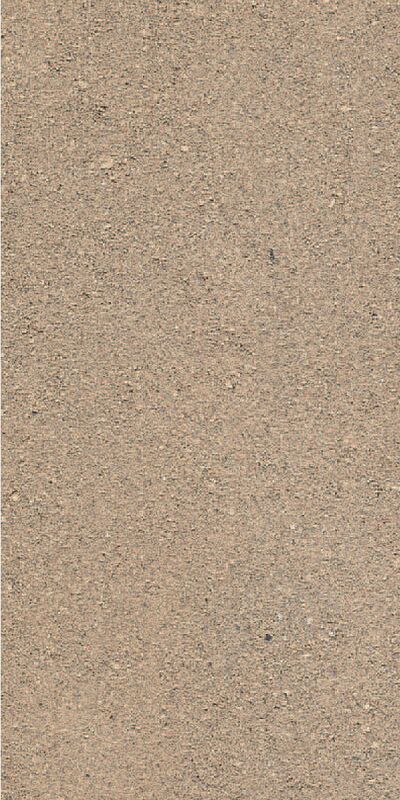

Textures and finishes

to suit any project

1 / 11

“Vobster Architectural's stone was the perfect choice for this application. We were installing what we consider to be the very best material available on the market.”

Shaun Henley, Managing Director - Henley Stone

More products

We’d love to hear from you

To request a sample or speak to a member of our team, get in touch with our office who will be happy to support you and answer any questions you may have.

T. +44 (0)203 968 7058 E. enquiries@vobsterarchitectural.co.uk

Contact